Green fire hydrants are critical within municipal water systems, representing a specific classification within standardized hydrant color-coding systems.

These distinctive green-colored hydrants communicate essential information to firefighting personnel regarding water pressure capabilities, source type, and operational parameters.

Understanding the significance of a green fire hydrant requires examining its technical specifications, geographic distribution patterns, and role within the comprehensive municipal firefighting infrastructure.

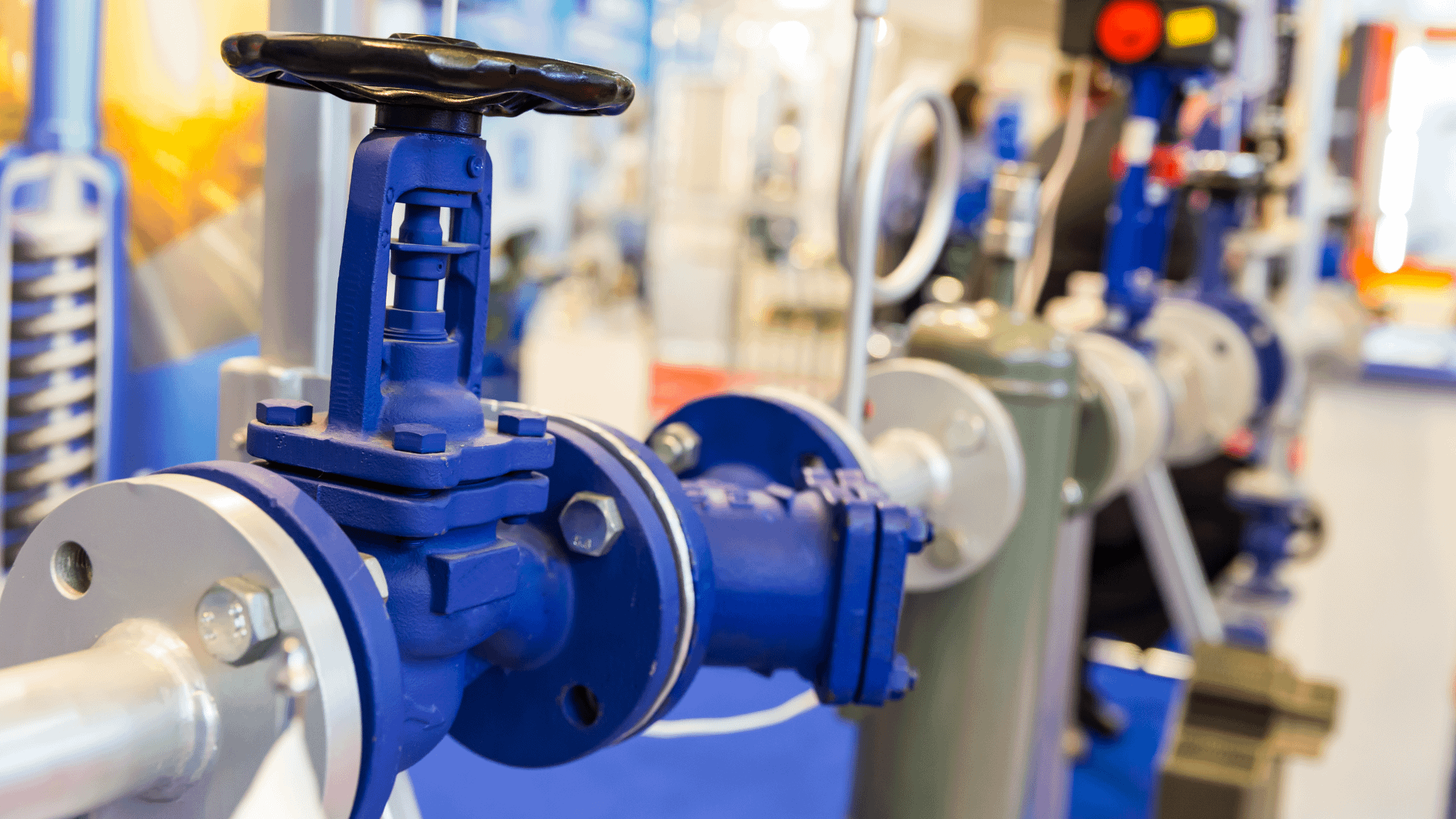

Technical Specifications of Green Fire Hydrants

Green fire hydrants typically denote water networks delivering flow between 1,000-1,499 gallons per minute measured at 20 psi residual pressure, though certain municipalities adjust these parameters based on local infrastructure capabilities.

Their distinctive green finish – applied through specialized powder-coating processes resistant to ultraviolet degradation – creates unmistakable visibility even during adverse weather conditions.

Most units feature standardized pentagon-shaped operating nuts requiring specialized wrenches, outlet configurations matching regional equipment standards, and internal pressure management components calibrated for specific water system characteristics.

Manufacturing tolerances adhere to strict AWWA specifications, depending on whether dry barrel or wet barrel designs are implemented.

Quality control testing includes hydrostatic pressure evaluation, typically conducted at twice the expected operating pressure for safety margin verification.

The Significance of Color in Fire Hydrant Systems

Fire hydrants feature various colors based on water flow capacity, pressure ratings, and water source types throughout different regions.

The fire hydrant color code system allows firefighters to assess water capabilities instantly during emergencies without performing tests that waste precious minutes.

Green hydrants generally connect to particular supply networks with defined pressure profiles or water from designated municipal sources, though exact specifications vary between water districts.

Several major metropolitan areas implemented these visual identification systems during the infrastructure standardization efforts, while some rural districts maintained independent systems until more recently.

Firefighter training programs typically dedicate specific modules to hydrant identification protocols, ensuring personnel can rapidly interpret these visual indicators regardless of which municipality they serve.

Geographic Distribution and Usage Patterns

Green hydrant distribution varies substantially between regions due to differing water infrastructure development timelines, local engineering practices, and regulatory frameworks adopted by various jurisdictions.

Northern states typically exhibit placement patterns reflecting greater concern for freeze protection, while southern installations often prioritize accessibility during seasonal flooding events.

Western municipalities frequently cluster these units near wildland-urban interface zones where firefighting water demands differ from urban core requirements.

Several mid-sized cities maintain detailed hydrant placement archives revealing how distribution evolved alongside population growth throughout different development periods.

These historical records demonstrate shifting priorities as fire protection engineering advanced.

Certain metropolitan areas feature notably higher green hydrant concentrations within older industrial corridors where infrastructure upgrades occurred during specific funding cycles that coincided with color-coding standardization efforts.

Commercial districts near transportation hubs typically demonstrate strategic green hydrant placement reflecting insurance underwriting requirements established during particular development phases.

University campuses often maintain specialized distribution patterns resulting from institutional capital improvement programs operating independently from surrounding municipal systems while maintaining interconnection capabilities.

High-density residential zones constructed during certain decades exhibit distinctive hydrant spacing characteristics reflecting building codes applicable during initial development.

Maintenance Requirements and Regulatory Compliance

Green hydrants necessitate structured maintenance regimens typically occurring biannually, with additional inspections following extreme weather events or nearby construction activities potentially affecting underground infrastructure.

Maintenance technicians utilize specialized torque wrenches when servicing operating mechanisms to prevent over-tightening that could damage internal components.

Winter maintenance protocols often include pump-out procedures that remove standing water from barrel sections susceptible to freezing in northern climates – a critical task scheduled before seasonal temperature drops.

Documentation practices evolved substantially following several high-profile litigation cases where inadequate record-keeping complicated liability determinations after system failures.

Current best practices involve electronic documentation systems, including photographic verification, GPS coordinates, and detailed condition assessments uploaded to centralized asset management databases accessible to multiple municipal departments.

Insurance providers frequently conduct independent audits reviewing these maintenance records when establishing premium rates for municipal coverage policies.

NFPA 291 compliance requires specific testing methodology, including precise flow measurement procedures conducted according to standardized protocols using calibrated equipment.

Testing typically occurs during off-peak demand periods to minimize disruption while maintaining representative data collection.

Larger municipalities often employ dedicated hydrant maintenance crews who develop specialized knowledge regarding specific system characteristics throughout their service territories – institutional knowledge that proves invaluable during emergency operations.

Integration with Modern Firefighting Technologies

Today’s emergency services increasingly incorporate green hydrant location data within sophisticated GIS mapping platforms, hydraulic modeling applications, and mobile response coordination systems accessible via vehicle-mounted terminals.

Field personnel commonly utilize tablet devices displaying hydrant distribution overlays with color-coding indicating precise water supply characteristics throughout their response jurisdiction.

Several major departments have implemented RFID tagging programs, enabling rapid electronic verification of green hydrant maintenance records during routine inspections or emergency deployments.

Predictive analytics software now incorporates historical flow data from green hydrants to optimize water delivery strategies during various emergency scenarios – capabilities unimaginable to earlier generations of firefighters.

These computational models account for seasonal pressure variations, infrastructure age variables, and anticipated demand fluctuations when generating tactical recommendations.

Certain forward-thinking municipalities have begun exploring acoustic monitoring technologies capable of detecting underground leakage near green hydrant connections before visible evidence appears at surface level.

This preventative approach significantly reduces maintenance costs while ensuring operational readiness during critical incidents.

Green hydrant maintenance records integration with enterprise asset management systems enables more precise capital improvement planning through data-driven decision support tools available to municipal managers.

Procurement Considerations for Municipal Authorities

Water authorities navigating procurement processes face multifaceted decisions balancing immediate budgetary constraints against long-term reliability concerns when selecting green hydrants.

Bid specifications typically reference AWWA Standards for dry-barrel hydrants or wet-barrel variants, depending on regional freeze concerns, while also incorporating locality-specific requirements addressing particular soil conditions, water chemistry variables, or operational practices unique to individual systems.

Purchasing officials increasingly specify domestically manufactured components following supply chain disruptions that affected replacement part availability during recent infrastructure maintenance cycles.

Total cost of ownership calculations extend beyond initial purchase price to include installation labor requirements, anticipated maintenance frequency projections, spare parts inventory considerations, and specialized tooling needs.

Municipalities participating in mutual aid agreements often coordinate procurement specifications, ensuring equipment compatibility across jurisdictional boundaries – standardization efforts particularly valuable during large-scale emergency response scenarios.

Extended warranty provisions receive scrutiny during bid evaluation, with progressive municipalities often specifying performance bonds covering initial operational periods.

Engineering departments frequently prepare detailed justification documentation supporting hydrant selection decisions, particularly when recommending premium-grade units commanding higher initial investment.

These analyses typically quantify projected savings through extended service lifespans, reduced maintenance requirements, and enhanced operational reliability during critical situations.

Procurement committees increasingly include representatives from emergency services alongside water department personnel, ensuring selection criteria adequately address firefighting operational requirements alongside water system maintenance considerations.

Hydrant Innovation and Future Perspectives

Green fire hydrants – often overlooked by passing pedestrians – represent vital components within complex municipal water delivery networks.

These units provide immediate visual cues regarding flow capacity specifications necessary for emergency personnel making split-second decisions.

Regional variation exists regarding exact shade specifications, with municipalities across northeastern states frequently adopting slightly different green hue requirements than their southwestern counterparts.

The practical implementation of standardized color-coding varies between jurisdictions, yet maintains sufficient consistency to enable cross-training of emergency personnel who may operate across multiple municipal boundaries.

Several municipalities have explored enhanced visibility options for green hydrants in areas prone to visual obstruction, including reflective banding, specialized paint formulations, and strategic positioning protocols.

Seasonal considerations impact maintenance schedules, with spring typically designated as optimal for comprehensive inspection programs following winter freeze-thaw cycles.

Records dating back to early metropolitan fire management systems demonstrate the evolution of hydrant classification approaches, with color-coding systems replacing earlier numerical designation protocols during infrastructure modernization initiatives.

Material science advancements continue influencing hydrant manufacturing processes, with contemporary units featuring enhanced corrosion resistance properties, improved valve seat materials, and optimized casting techniques.

The projected service duration of properly maintained green hydrants typically ranges between 50-75 years, depending on environmental factors, water chemistry variables, and operational demands.

Installation depth requirements vary according to frost line considerations, with northern municipalities generally specifying deeper placement parameters than southern jurisdictions.

This regional adaptation highlights the practical engineering considerations governing hydrant deployment standards across diverse geographic regions.New England Manufacturing is here if you need further support or information. Contact our technical specialists today to gain valuable insights.