The 8 Best Types of Flow Measurement for Fire Protection & Beyond: A 2025 Comprehensive Guide

Accurate flow measurement is the unsung hero of countless critical systems, from ensuring the reliable delivery of water for firefighting to optimizing complex industrial processes.

For professionals in fire protection, insurance underwriting, fire pump system installation, and fire departments, understanding the nuances of flow measurement isn’t just beneficial; it’s essential for safety, efficiency, and regulatory compliance.

This comprehensive guide will demystify the world of flow measurement by exploring the 8 best types of flow measurement technologies available today. We’ll delve into the working principles of each type, analyze their pros and cons, and highlight their ideal applications, particularly within the context of fire protection and related industries.

Understanding these diverse methods will empower you to make informed decisions, optimize your systems, and ensure accurate, reliable flow data in any scenario.

1. Differential Pressure Flow Meters: The Versatile Workhorse

Differential Pressure (DP) flow meters are among the most established and widely used flow measurement technologies. Their popularity stems from their versatility, relative simplicity, and cost-effectiveness. These meters operate based on a fundamental principle of fluid dynamics: Bernoulli’s Principle.

1.1 Working Principle:

DP flow meters introduce a constriction into the flow stream, creating a pressure difference. This constriction can take various forms, including:

- Orifice Plates: A thin plate with a precisely sized hole, creating a simple and economical constriction.

- Venturi Tubes: A gradually converging and diverging section, offering lower pressure loss compared to orifice plates.

- Flow Nozzles: Similar to Venturi tubes but with a less pronounced diverging section, providing a balance between pressure loss and cost.

- Pitot Tubes: These measure the difference between the stagnation pressure (total pressure) and the static pressure to determine velocity at a specific point in the flow stream. While technically a point measurement, they are often used to infer overall flow in pipes and ducts.

By measuring the pressure difference (differential pressure) created by the constriction, and knowing the characteristics of the constriction and the fluid, the flow rate can be accurately calculated. This relationship is governed by well-established hydraulic equations and standards like ISO 5167.

1.2 Pros of Differential Pressure Flow Meters:

- Versatility: Suitable for a wide range of liquids, gases, and steam.

- Cost-Effective: Generally less expensive than many other flow meter types, especially orifice plates.

- Simplicity: Relatively simple in design and operation.

- Established Technology: Well-understood technology with extensive industry experience and standards.

- Wide Range of Sizes: Available for various pipe sizes and flow rates.

1.3 Cons of Differential Pressure Flow Meters:

- Pressure Loss: Introduce a permanent pressure loss in the system, especially orifice plates. Venturi tubes and flow nozzles offer reduced pressure loss.

- Accuracy Can Be Affected by Fluid Properties: Changes in fluid density and viscosity can impact accuracy if not accounted for.

- Straight Run Requirements: Often require significant straight pipe runs upstream and downstream of the meter for accurate readings.

- Maintenance: Can be susceptible to clogging or erosion, particularly with dirty fluids.

1.4 Applications:

- Water and Wastewater Treatment: Measuring flow in pipelines and treatment processes.

- Oil and Gas: Applications in pipelines, refineries, and processing plants.

- Chemical Processing: Measuring flow of various chemicals and process fluids.

- Power Generation: Steam flow measurement in boilers and turbines.

- HVAC Systems: Monitoring flow in chilled water and heating systems.

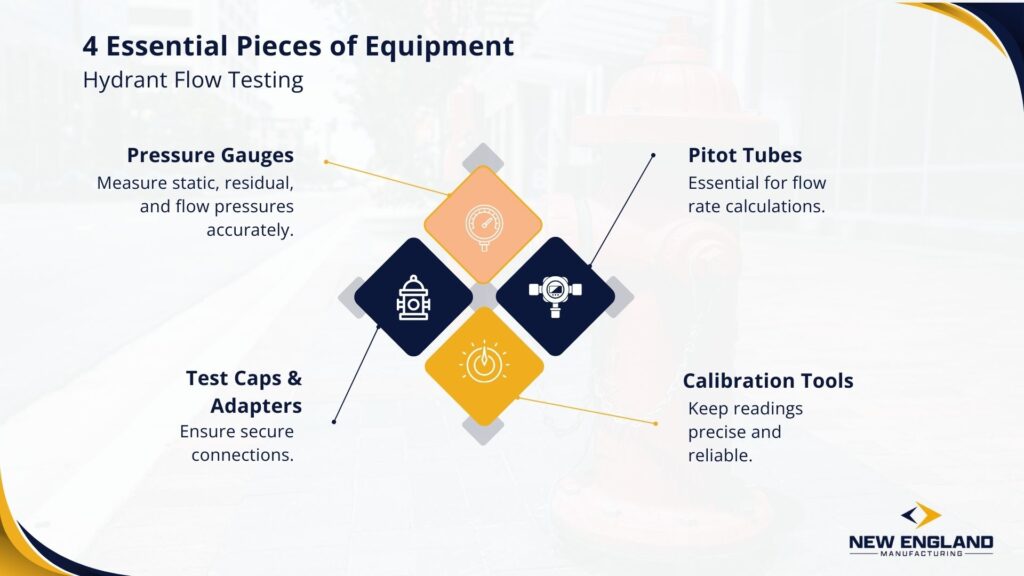

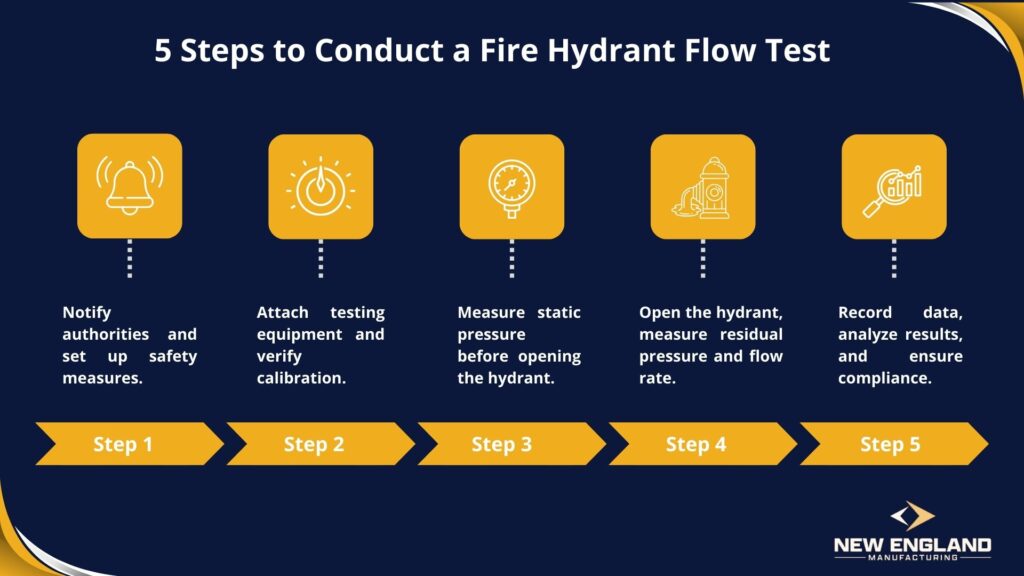

- Fire Hydrant Flow Testing: Pitot tubes, in particular, are a cornerstone of fire hydrant flow testing, as discussed in our guide on What is a Pitot Tube?. They are crucial for determining flow rates during Fire Hydrant Testing and Fire Hydrant Flow Tests.

2. Turbine Flow Meters: Precision for Clean Liquids and Gases

Turbine flow meters are known for their high accuracy and repeatability, making them ideal for applications requiring precise volume measurement of clean liquids and gases.

2.1 Working Principle:

These meters utilize a multi-bladed rotor that rotates freely within the flow stream. As fluid passes through the meter, it impinges on the turbine blades, causing the rotor to spin at a speed proportional to the flow velocity.

The rotor’s rotation is typically detected by an external sensor, often magnetic or inductive, which generates pulses. These pulses are then converted into a flow rate measurement.

2.2 Pros of Turbine Flow Meters:

- High Accuracy: Offer excellent accuracy, often within ±0.5% or better.

- Wide Flow Range: Can handle a broad range of flow rates.

- Good Repeatability: Provide consistent readings over time.

- Relatively Compact: Generally smaller than some other flow meter types for equivalent pipe sizes.

- Suitable for Clean Fluids: Well-suited for clean liquids and gases.

2.3 Cons of Turbine Flow Meters:

- Moving Parts: Contain moving parts (the turbine rotor), which can be subject to wear and require maintenance.

- Sensitivity to Fluid Viscosity: Accuracy can be affected by changes in fluid viscosity.

- Require Clean Fluids: Not suitable for dirty fluids or fluids containing solids that could damage or impede the rotor.

- Pressure Drop: Introduce a moderate pressure drop in the system.

- Orientation Sensitivity: Some turbine meters are sensitive to installation orientation.

2.4 Applications:

- Oil and Gas Industry: Custody transfer measurement of petroleum products, natural gas, and liquefied gases.

- Chemical Industry: Precise metering of chemicals and solvents.

- Water Distribution: Accurate measurement of potable water flow.

- Pharmaceuticals: Metering of high-purity liquids.

- Cryogenic Fluids: Specialized turbine meters are available for cryogenic applications.

- Fuel Measurement: Accurate fuel consumption monitoring.

Expert Tip: Looking to upgrade your flow testing equipment? New England Manufacturing offers complete testing kits designed for reliability and ease of use. Our NIST-traceable calibration services ensure your equipment meets all current standards.

View our professional testing kits →

Beyond equipment, proper testing requires expertise and attention to detail. That’s why we offer technical support to all our customers, ensuring you get the most accurate results from your testing program.

3. Electromagnetic Flow Meters (Magmeters): Unobstructed Flow for Conductive Fluids

Electromagnetic flow meters, often called “magmeters,” are ideal for measuring the flow of conductive liquids, slurries, and pastes. Their key advantage is that they offer an unobstructed flow path, minimizing pressure loss and making them suitable for delicate or abrasive fluids.

3.1 Working Principle:

Magmeters operate based on Faraday’s Law of Electromagnetic Induction. A magnetic field is generated by coils external to the flow tube. As a conductive fluid flows through this magnetic field, it induces a voltage in the fluid that is proportional to the flow velocity.

Electrodes mounted in the flow tube wall, but isolated from the fluid, detect this induced voltage. The meter then converts this voltage signal into a volumetric flow rate.

3.2 Pros of Electromagnetic Flow Meters:

- Unobstructed Flow Path: No moving parts or obstructions in the flow stream, resulting in minimal pressure loss.

- Suitable for Dirty and Abrasive Fluids: Can handle conductive liquids containing solids, slurries, and pastes.

- High Accuracy: Offer good accuracy and repeatability.

- Low Maintenance: No moving parts mean reduced maintenance requirements.

- Wide Range of Sizes: Available for very large pipe sizes.

- Bi-directional Measurement: Can measure flow in both directions.

3.3 Cons of Electromagnetic Flow Meters:

- Conductive Fluids Required: Only work with conductive fluids (liquids with a certain level of electrical conductivity). Non-conductive liquids like oil and pure water cannot be measured directly.

- More Expensive: Generally more expensive than DP flow meters.

- Electrode Fouling: Electrodes can become fouled or coated in certain applications, affecting accuracy.

- Sensitivity to External Magnetic Fields: Can be affected by strong external magnetic fields.

3.4 Applications:

- Water and Wastewater: Measuring flow of raw water, treated water, sewage, and sludge.

- Chemical Processing: Handling corrosive and aggressive conductive chemicals.

- Mining and Mineral Processing: Measuring flow of slurries and ore concentrates.

- Food and Beverage: Applications in food processing plants where hygiene and minimal obstruction are important.

- Pulp and Paper: Measuring flow of pulp slurries.

- Pharmaceuticals: Suitable for conductive pharmaceutical liquids.

4. Ultrasonic Flow Meters: Non-Invasive Measurement from Outside the Pipe

Ultrasonic flow meters offer a significant advantage: they can measure flow non-invasively, from outside the pipe. This makes them ideal for applications where it’s undesirable or impossible to cut into the pipeline, such as retrofits, hazardous fluids, or large diameter pipes.

4.1 Working Principle:

Ultrasonic flow meters utilize sound waves to measure flow velocity. There are two main types:

- Transit-Time Flow Meters (Time-of-Flight): These meters send ultrasonic signals both upstream and downstream through the fluid. The difference in the transit time of the signals is directly proportional to the flow velocity. Sound waves travel faster in the direction of flow and slower against it.

- Doppler Flow Meters: These meters rely on the Doppler effect. They transmit ultrasonic waves into the fluid, and the frequency shift of the reflected waves from particles or bubbles in the fluid is measured. This frequency shift is proportional to the flow velocity.

4.2 Pros of Ultrasonic Flow Meters:

- Non-Invasive and Clamp-On Options: Can be installed without cutting into the pipe, offering easy installation and retrofitting. Clamp-on versions are available for temporary measurements.

- Suitable for Various Fluids: Can measure liquids, gases, and even some slurries (depending on the type and application).

- Low Pressure Drop: Transit-time meters generally have very low pressure drop. Doppler meters have no pressure drop as they are external.

- Portable Options: Clamp-on ultrasonic meters are often portable and can be moved between measurement locations.

- Suitable for Large Pipes: Well-suited for large diameter pipes where other meter types might be impractical or expensive.

4.3 Cons of Ultrasonic Flow Meters:

- Fluid Must Transmit Sound: The fluid must be able to effectively transmit ultrasonic waves. Highly aerated liquids or fluids with high solids content can be challenging for transit-time meters (Doppler may be more suitable in some cases).

- Pipe Material Limitations: Pipe material must allow sound transmission. Lined pipes or pipes with thick walls can pose challenges.

- Accuracy Can Be Affected by Fluid Properties and Installation: Accuracy can be influenced by fluid properties, pipe conditions, and proper transducer installation.

- Cost: Can be more expensive than some other flow meter types, especially for advanced transit-time models.

4.4 Applications:

- Water and Wastewater: Measuring flow in pipelines, distribution networks, and treatment plants.

- Chemical and Petrochemical: Suitable for various liquids and gases, including hazardous fluids due to non-invasive nature.

- HVAC and Building Automation: Monitoring flow in chilled water, heating water, and air ducts.

- Power Generation: Cooling water and process water flow measurement.

- Temporary Flow Measurement and Audits: Clamp-on meters are ideal for temporary flow surveys and system audits.

5. Vortex Flow Meters: Robust and Reliable for Steam, Gas, and Liquids

Vortex flow meters are known for their robustness, reliability, and versatility in measuring the flow of liquids, gases, and steam. They are particularly well-suited for steam applications.

5.1 Working Principle:

Vortex meters operate based on the principle of vortex shedding. A bluff body (a non-streamlined obstruction) is placed in the flow stream. As fluid flows past this bluff body, it creates a series of swirling vortices downstream.

The frequency at which these vortices are shed is directly proportional to the flow velocity. A sensor, often piezoelectric, thermal, or ultrasonic, detects the vortex shedding frequency and converts it into a flow rate measurement.

5.2 Pros of Vortex Flow Meters:

- Versatile for Liquids, Gases, and Steam: Effective across a wide range of fluids, including steam, gases, and liquids.

- No Moving Parts: Robust and reliable with no moving parts to wear out.

- Good Accuracy and Repeatability: Offer good accuracy and consistent readings.

- Wide Temperature and Pressure Ranges: Can operate in a broad range of temperature and pressure conditions.

- Relatively Low Maintenance: Due to the absence of moving parts, maintenance is generally low.

5.3 Cons of Vortex Flow Meters:

- Requires Minimum Flow Rate: Need a minimum flow velocity to generate vortices.

- Sensitive to Vibrations: Can be sensitive to external vibrations, which can affect vortex detection.

- Straight Run Requirements: May require straight pipe runs upstream of the meter for optimal performance.

- Pressure Drop: Introduce a moderate pressure drop in the system.

5.4 Applications:

- Steam Measurement: Widely used for steam flow measurement in industrial and commercial applications.

- Natural Gas and Compressed Air: Measuring flow of natural gas, compressed air, and other industrial gases.

- Chemical Processing: Suitable for various chemical liquids and gases.

- HVAC and Building Automation: Monitoring steam and hot water flow.

- Power Generation: Steam and process fluid flow measurement.

6. Coriolis Mass Flow Meters: The Gold Standard for Mass Flow Measurement

Coriolis mass flow meters are considered the “gold standard” when it comes to direct mass flow measurement. Unlike volumetric flow meters that measure volume and infer mass, Coriolis meters directly measure mass flow rate, making them highly accurate and independent of fluid property changes.

6.1 Working Principle:

Coriolis meters utilize the Coriolis effect, a phenomenon related to rotating reference frames. The meter typically consists of one or more vibrating tubes through which the fluid flows.

When fluid flows through the vibrating tubes, it experiences a Coriolis force. This force causes a twisting or deflection of the tubes, which is directly proportional to the mass flow rate of the fluid. Sensors detect this deflection and convert it into a mass flow measurement.

6.2 Pros of Coriolis Mass Flow Meters:

- Direct Mass Flow Measurement: Measure mass flow directly, eliminating the need for density or temperature compensation in many applications.

- High Accuracy: Offer the highest accuracy among flow meter types, often within ±0.1% or better.

- Independent of Fluid Properties: Measurement is largely unaffected by changes in fluid density, viscosity, temperature, and pressure.

- Multi-Parameter Measurement: Can simultaneously measure mass flow rate, density, and temperature.

- Suitable for Liquids and Gases: Available for both liquids and gases.

6.3 Cons of Coriolis Mass Flow Meters:

- High Cost: Significantly more expensive than most other flow meter types.

- Larger and Heavier: Generally larger and heavier than other flow meters for equivalent pipe sizes.

- Pressure Drop: Introduce a moderate pressure drop in the system.

- Sensitivity to External Vibrations: Can be sensitive to external vibrations, requiring careful installation and vibration isolation in some cases.

- Installation Requirements: May have more stringent installation requirements compared to some other types.

6.4 Applications:

- Custody Transfer: Used for high-accuracy custody transfer applications in oil and gas, chemical, and other industries where precise billing and inventory control are critical.

- Chemical Processing: Precise dosing and batching of chemicals in critical processes.

- Pharmaceuticals: High-accuracy metering of pharmaceutical ingredients.

- Food and Beverage: Applications requiring precise ingredient metering and process control.

- Aerospace and Aviation: Fuel flow measurement in aircraft and spacecraft.

7. Positive Displacement Flow Meters: Accuracy for Viscous Liquids and Batching

Positive Displacement (PD) flow meters are unique in that they measure flow by mechanically trapping and displacing a known volume of fluid with each rotation or cycle of internal components. This direct volumetric measurement makes them highly accurate, especially for viscous liquids and batching applications.

7.1 Working Principle:

PD meters utilize various mechanical designs, including:

- Oval Gear Meters: Two intermeshing oval gears rotate, trapping and displacing fluid.

- Rotating Piston Meters: A piston oscillates within a chamber, displacing a fixed volume of fluid with each cycle.

- Nutating Disk Meters: A disk “nutates” or wobbles within a chamber, displacing fluid volume.

With each rotation or cycle, a precise volume of fluid passes through the meter. By counting the number of rotations or cycles, the total volume of fluid that has passed through is determined.

7.2 Pros of Positive Displacement Flow Meters:

- High Accuracy: Offer excellent accuracy and repeatability, particularly for viscous liquids.

- Direct Volume Measurement: Measure volume directly, without relying on fluid properties or inferential calculations.

- Suitable for Viscous Liquids: Perform well with viscous liquids like oils, fuels, and syrups.

- Wide Viscosity Range: Can handle a broad range of viscosities.

- Good for Batching and Metering: Ideal for batching and dispensing applications where precise volume control is needed.

7.3 Cons of Positive Displacement Flow Meters:

- Moving Parts: Contain moving parts that are subject to wear and require maintenance.

- Pressure Drop: Introduce a moderate pressure drop in the system.

- Limited Flow Range: May have a more limited flow range compared to some other types.

- Sensitivity to Debris: Not suitable for dirty fluids or fluids containing large solids that could damage or jam the moving parts.

- Orientation Sensitivity: Some PD meters are sensitive to installation orientation.

7.4 Applications:

- Fuel Dispensing: Gasoline pumps and fuel oil delivery trucks commonly use PD meters for accurate fuel measurement.

- Oil and Gas: Metering of viscous oils and lubricants.

- Chemical Industry: Batching and dispensing of chemicals, especially viscous fluids.

- Food and Beverage: Metering of syrups, sauces, and other viscous food products.

- Hydraulic Systems: Flow measurement in hydraulic circuits.

8. Thermal Mass Flow Meters: Direct Mass Flow for Gases

Thermal Mass Flow Meters are specifically designed for direct mass flow measurement of gases. They are particularly useful in applications where gas density or composition may vary, as they measure mass flow independent of these changes.

8.1 Working Principle:

Thermal mass flow meters operate on the principle of heat transfer. They introduce a small amount of heat into the gas stream and measure how much heat is carried away by the flowing gas.

There are typically two temperature sensors: one upstream and one downstream of a heated element. The temperature difference between these sensors is directly related to the mass flow rate of the gas. The higher the mass flow rate, the more heat is carried away, and the smaller the temperature difference.

8.2 Pros of Thermal Mass Flow Meters:

- Direct Mass Flow Measurement for Gases: Measure mass flow directly for gases, eliminating the need for temperature and pressure compensation.

- Suitable for Gas Mixtures: Less sensitive to changes in gas composition compared to volumetric flow meters.

- Low-Pressure Drop: Typically have very low-pressure drop.

- Wide Range of Gases: Can be used for a variety of gases.

- Digital Output: Often provide digital outputs for easy integration with control systems.

8.3 Cons of Thermal Mass Flow Meters:

- Gas Specific Calibration: Calibration is typically gas-specific. Changing the gas type may require recalibration.

- Sensitivity to Gas Properties: While less sensitive than volumetric meters, accuracy can still be affected by significant changes in gas properties outside the calibrated range.

- Limited to Gases: Primarily designed for gases, not suitable for liquids.

- Contamination Sensitivity: Sensor contamination can affect accuracy.

8.4 Applications:

- Industrial Gas Measurement: Process gas flow measurement in chemical plants, refineries, and manufacturing facilities.

- Semiconductor Manufacturing: Gas flow control in semiconductor fabrication processes.

- Environmental Monitoring: Stack gas monitoring and emissions control.

- Analytical Instruments: Gas flow control in gas chromatography and mass spectrometry.

- HVAC and Building Automation: Air flow measurement in ventilation systems.

Factors to Consider When Choosing a Flow Meter

Selecting the right flow meter is crucial for accurate and reliable measurements. Here are key factors to consider:

- Fluid Type: Is it a liquid, gas, or steam? Is it clean, dirty, viscous, conductive, or corrosive? Different flow meter types are suited for different fluids.

- Flow Rate and Range: What is the expected flow rate and the required measurement range? Ensure the meter can handle the minimum and maximum flow rates.

- Accuracy Requirements: What level of accuracy is needed for the application? Custody transfer applications demand the highest accuracy, while less critical applications may tolerate lower accuracy.

- Pressure and Temperature: What are the operating pressure and temperature conditions? Choose a meter rated for the expected conditions.

- Pressure Drop: How much pressure drop can be tolerated in the system? Consider meters with low pressure drop if energy efficiency is a concern.

- Installation Requirements: Are there straight run requirements or orientation limitations? Consider the ease of installation and any special requirements.

- Maintenance and Reliability: What are the maintenance requirements and expected lifespan of the meter? Consider meters with low maintenance and high reliability for long-term operation.

- Cost: What is the budget for the flow meter? Balance cost with performance and features.

- Output and Communication: What type of output signal is required (analog, digital, pulse)? Does it need to communicate with a control system?

- Industry Standards and Regulations: Are there specific industry standards or regulations that must be met (e.g., NFPA standards in fire protection)

Conclusion: Choosing the Right Flow Measurement for Your Needs

Navigating the world of flow measurement can seem complex, but understanding the fundamental principles and applications of these 8 best types of flow meters is the first step towards informed decision-making. From the versatility of Differential Pressure meters to the ultimate accuracy of Coriolis technology, each type offers unique advantages and is best suited for specific applications.

For professionals in fire protection and related fields, accurate flow measurement is not just about data collection; it’s about ensuring the reliability of critical safety systems. Whether you’re conducting fire hydrant flow tests, verifying fire pump performance, or managing water distribution networks, selecting the appropriate flow measurement technology is paramount for safety and compliance.

By carefully considering the factors outlined and understanding the strengths and weaknesses of each flow meter type, you can confidently choose the best solution for your specific needs, ensuring accurate, reliable, and efficient flow measurement in any application.

Partner with the Flow Measurement Experts

At New England Manufacturing, we understand the critical importance of accurate and reliable flow measurement, especially in demanding applications like fire protection. With nearly a century of experience since 1925, we are committed to providing high-quality flow measurement equipment and expert support to professionals like you. While we are recognized for our contributions to fire hydrant testing equipment, our expertise extends to a broad range of flow measurement solutions.

Why Choose New England Manufacturing?

- Nearly 100 years of industry experience in measurement and testing equipment.

- Veteran-owned and operated, dedicated to quality and precision.

- Expertise in flow measurement principles across various technologies.

- NIST-traceable calibration services to ensure accuracy and compliance.

- A comprehensive range of testing kits and individual components.

- Dedicated technical support to assist with equipment selection and application.

- Fast shipping and competitive pricing.

Ready to discuss your flow measurement needs or upgrade your equipment? Contact our expert team today:

- 📞 Call us: 304-727-0931

- 🌐 Visit: www.nemfg.com

- ✉️ Email: sales@nemfg.com

Let us help you ensure accurate and reliable flow measurements for your critical systems.

Mark R.

With a strong foundation in industrial safety and fire protection systems, Mark R. specializes in creating clear, technical, and compliance-driven content. Writing for SafeTech Reports, he covers topics such as fire hydrant testing, PPE protocols, emergency procedures, and smart technology integration in safety systems. His work ensures that professionals stay informed on the latest regulations, best practices, and emerging trends in safety and infrastructure maintenance.

Get in touch

We usually respond within 24 hours

Need Reliable Water Flow Test Equipment?

For over 70 years, New England Manufacturing has been the trusted source for fire hydrant and water flow testing kits. From pitot gauge kits to custom test kits, we provide precision, durability, and expert calibration to meet your needs.

- Custom-built test kits

- High-quality pressure gauges

- Reliable calibration services