Globe valves are key parts that control water flow in many systems. They help stop water completely or control how much flows through pipes.

These valves work great for fire protection systems, water plants, and factories. Water flow specialists use them because they last long and work well.

What Is A Globe Valve?

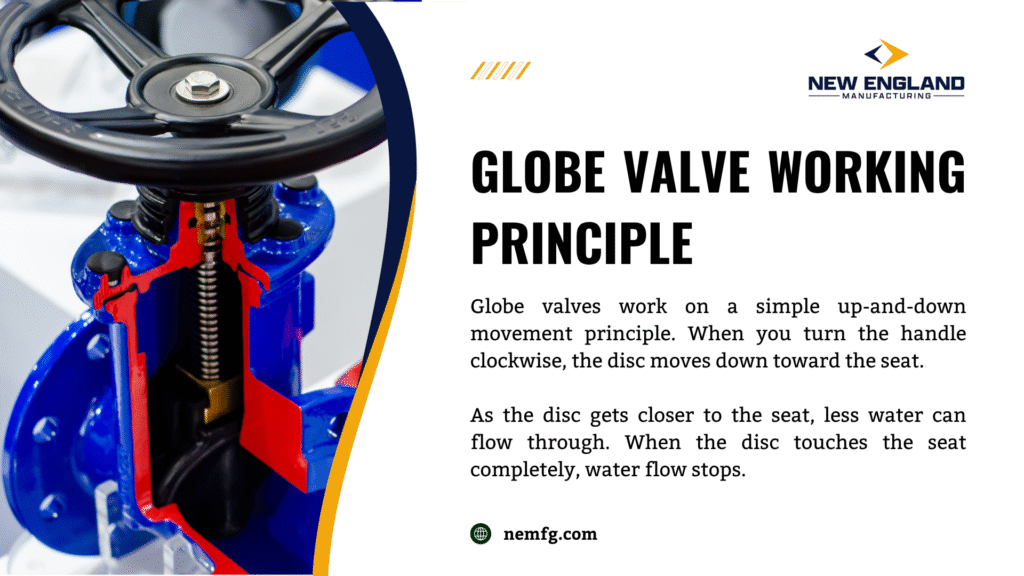

A globe valve is a simple valve that stops or controls water flow. It has a round disc that moves up and down to block or allow water through.

The valve gets its name from its round body shape. Modern versions of these valves might look different, but they work the same way.

When you turn the handle, the disc inside moves up or down. This opens or closes the path for water to flow through.

What is the Purpose of a Globe Valve, and what is it Used For?

These valves have two main jobs: stopping water completely and controlling flow rate. They work better than other valves when you need exact control over water flow.

The main purpose is to give operators full control over their water systems. And this helps you to keep water pressure safe and systems run smoothly.

Globe valves are perfect for systems that need frequent adjustments. They handle high-pressure water without breaking or leaking.

Common Globe Valve Applications

Application | Why Globe Valves Work Best |

Fire Protection Systems | Quick shut-off and pressure control |

Water Treatment Plants | Precise flow control for chemical mixing |

Heating Systems | Temperature control through flow regulation |

Industrial Cooling | Exact water flow for equipment protection |

If you’re working with fire hydrant systems, you need to know about proper fire hydrant flow test procedures, because they help you to make sure your globe valves perform correctly.

What is the Most Common Application of a Globe Valve?

The most common use for globe valves is in fire sprinkler systems. These systems need valves that can shut off water fast and control pressure perfectly.

Fire departments also use these types of valves in their equipment. They help you to control water flow during emergencies and testing.

Many water companies use these valves at pump stations. These valves control how much water flows to different areas of town.

Globe Valve vs Gate Valve Comparison

Feature | Globe Valve | Gate Valve |

Flow Control | Excellent precision | On/off only |

Pressure Drop | Higher | Lower |

Shut-off Quality | Very tight seal | Good seal |

Maintenance | Easy to service | Harder to repair |

Cost | More expensive | Less expensive |

Globe valves cost more than gate valves but give better control. Gate valves work well for simple on/off jobs.

When you need to adjust flow often, globe valves are a better choice. Gate valves work best when you just need to turn water on or off.

Types of Globe Valves

There are three main types of globe valves used in water systems. Each type works best for different jobs and pressure levels.

- Straight-Through Valves

These are the most common globe valves you’ll see. Water flows straight through them in one direction.

They work great for most water control jobs. The simple design makes them easy to fix and maintain.

- Angle Valves

Angle valves turn the water flow 90 degrees. They save space and reduce the need for extra pipe fittings.

These valves work well at pipe corners. They help reduce pressure loss in some systems.

- Three-Way Valves

Three-way valves can mix water from two sources or split the flow. They have three openings instead of two.

Water treatment plants use these to mix chemicals with water. They help create the exact water quality needed.

Globe Valve Materials

Material | Best For | Why It Works |

Brass | Low-pressure water | Easy to work with, affordable |

Stainless Steel | High-pressure systems | Strong, doesn’t rust |

Cast Iron | Large water lines | Handles big flows, lasts long |

Bronze | Marine applications | Resists saltwater damage |

As a water flow specialist, you should select materials based on your system’s specific needs.

For most water applications, brass globe valves work perfectly. They cost less and are easy to install and maintain.

How is a Globe Valve Made?

Globe valves start with a round or oval body made from metal. The body gets machined to create smooth surfaces where parts fit together.

The valve seat gets carefully shaped to match the disc perfectly. This creates a tight seal that stops all water flow.

The body holds all the other parts and connects to the pipes. It’s usually made from brass, steel, or iron depending on the job.

The disc moves up and down to control water flow. It has a smooth surface that presses against the seat to stop water.

The stem connects the handle to the disc inside. When you turn the handle, the stem moves the disc up or down.

The bonnet covers the top of the valve and holds the stem. It can be removed for maintenance and repairs.

Manufacturing Process

First, workers cast or machine the valve body to exact specifications. They create smooth surfaces and precise threads for pipe connections.

Next, they machine the valve seat to create a perfect sealing surface. The disc gets shaped to match this seat exactly.

The stem gets machined with threads that match the bonnet. This allows smooth movement when operators turn the handle.

Finally, all parts get assembled and tested for leaks. Each valve must pass pressure tests before leaving the factory.

How Water Flows Through Globe Valves

Water enters the valve and hits the disc from below. This design helps create a tight seal when the valve closes.

The disc shape forces water to change direction as it flows through. This creates some pressure loss but gives excellent control.

When the valve opens, water flows around the disc and out the other side. The amount of opening controls how much water flows.

Pressure Control Benefits

Globe valves give operators exact control over water pressure. Small handle movements create small changes in flow rate.

This precise control helps protect equipment from pressure damage. It also helps maintain steady water pressure for users.

Many water systems use these valves with water pressure gauges to monitor system performance. This combination gives operators complete control over their systems.

Globe Valve Installation and Maintenance

Proper installation starts with checking pipe alignment and valve orientation. These valves work best when installed with the flow going up through the disc.

Most of these valves have an arrow showing the correct flow direction. Installing them backward reduces performance and can cause damage.

- Installation Best Practices

Always support heavy valves with proper pipe supports. Large valves can stress pipe joints if not supported correctly.

Check that pipe threads match the valve connections exactly. Mismatched threads can cause leaks and system problems.

For fire protection systems, follow local codes for valve placement. Some areas require specific valve locations for safety.

- Maintenance Requirements

Globe valves need regular checks to ensure proper operation. Look for leaks around the stem and body connections.

Test valve operation monthly by turning the handle through its full range. Stiff operation might mean the valve needs service.

If you’re maintaining fire protection equipment, understanding pressure gauge calibration helps ensure your system measurements stay accurate.

- Common Problems and Solutions

Problem | Cause | Solution |

Handle is hard to turn | Worn stem threads | Replace the stem or rebuild the valve |

Water leaks from the stem | Bad packing | Replace the packing material |

Won’t shut off completely | Damaged seat or disc | Resurface or replace parts |

Pressure loss | Wrong valve size | Install the correct size valve |

Most globe valve problems come from normal wear over time. Regular maintenance prevents many issues before they cause system problems.

When these valves start leaking, fix them quickly to prevent water waste. Small leaks often become big problems if ignored.

Choosing the Right Globe Valve

Size selection depends on your pipe size and flow requirements. The valves should match your pipe size for best performance.

Pressure rating must exceed your system’s maximum pressure. Choose valves rated at least 50% higher than the normal operating pressure.

Flow rate determines the valve size you need for your system. Larger valves handle more water but cost more to buy and install.

Pipe size usually matches valve size for most applications. Sometimes, smaller valves work fine for control applications.

For fire protection systems that require fire hydrant testing, make sure your globe valves can handle the test pressures safely.

Water temperature affects which materials work best for your application. Hot water systems need materials that won’t expand too much.

Chemical compatibility matters for water treatment applications. Some chemicals can damage certain valve materials over time.

Cost considerations balance initial price against long-term maintenance needs. Cheaper valves might cost more over time if they need frequent repairs.

Globe Valve Performance in Different Systems

Fire protection systems rely on these kinds of valves for reliable operation. These valves must work perfectly every time, even after sitting unused for months.

- Industrial Applications

Manufacturing plants use the valves to control cooling water flow. Equipment protection depends on maintaining exact water flow rates.

Power plants rely on these types of valves for precise steam and water control. These high-pressure applications demand the best valve performance.

- Municipal Water Systems

City water departments use globe valves at pump stations and treatment plants. Flow control helps maintain steady pressure throughout the distribution system.

These valves help manage water pressure during peak usage times. They also isolate sections for maintenance and repairs.

If your system includes flow measurement equipment, globe valves help create the steady flow conditions needed for accurate readings.

Troubleshooting Globe Valve Issues

Check water pressure upstream and downstream of the valve. Big pressure differences might indicate internal problems.

Look for signs of corrosion or damage on external valve parts. External damage often indicates internal problems, too.

For systems with pitot gauges, use them to measure flow rates and pressure drops across the valve.

Age and condition determine whether to repair or replace these valves. Valves over 20 years old often cost more to repair than replace.

Availability of repair parts affects the decision, too. Obsolete valves might need replacement even if otherwise repairable.

Consider system criticality when making repair decisions. Critical systems might need new valves for maximum reliability.

Key Takeaways

The globe valves ensure perfect flow control for water systems, irrespective of size. Due to their simple design, extremely reliable operation and maintenance are possible.

Choose for applications requiring precise flow regulation or frequent operation. They are more costly than a gate valve, but worth it because of superior control applications.

Proper installation and maintenance will keep the valves operating reliably for decades. Follow recommendations from the manufacturers for best results.

For fire protection and critical water systems where reliability and performance are needed, this type has been considered because of its proven design and has been assisting water flow specialists worldwide.

New England Manufacturing, has been operating for 100 years as the #1 company to provide high-quality water test equipment. If you’d like expert help selecting, installing, or maintaining your globe valve systems, without worrying about flow control issues or unexpected failures, become part of our 80k satisfied customers by emailing us at sales@nemfg.com or by giving us a call.