If you work with water systems, it’s important to know exactly how much water is moving through your pipes. Understanding how water flow meters work can be the difference between getting the job done right and running into expensive problems.

So in this article, we’ve got you covered with all the information you need to know about water flow meters. You will learn how each type works and which is the best for your specific needs.

What Is a Water Flow Meter?

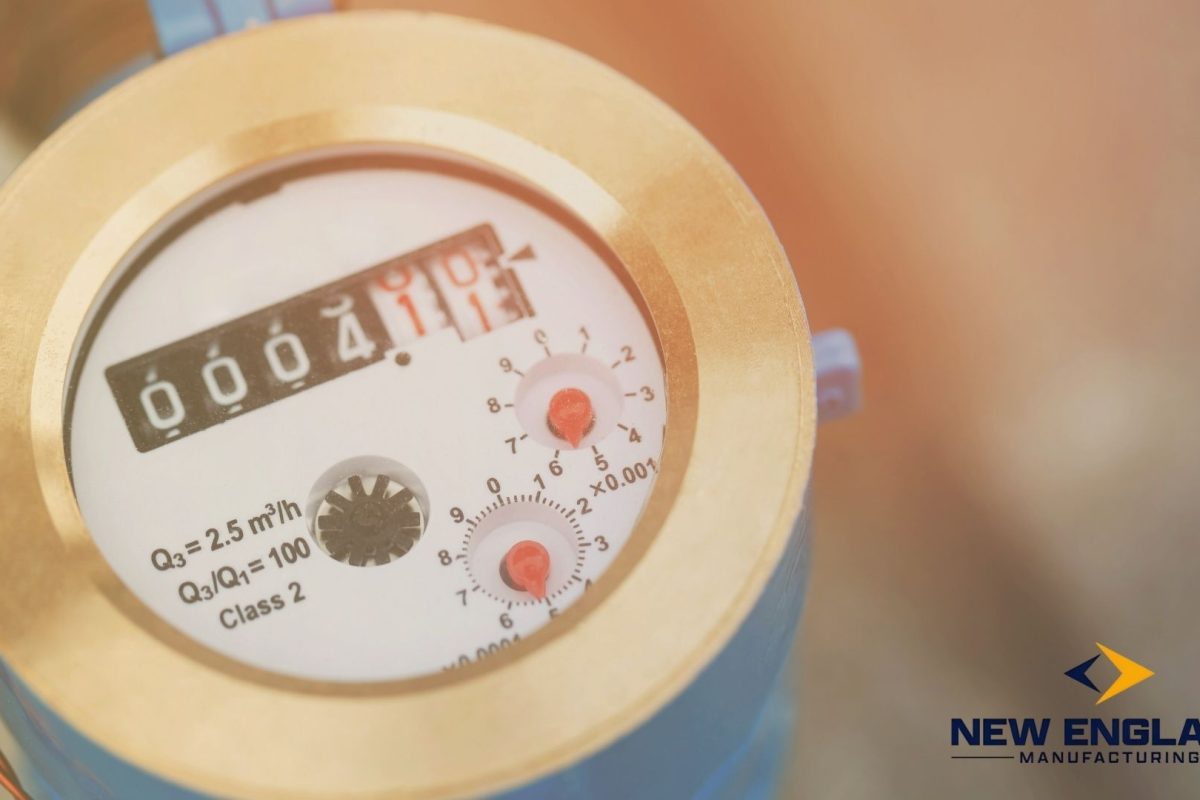

A water flow meter is a device that measures how much water moves through pipes. These meters tell you the exact amount of water passing through at any given time.

Water flow meters work by detecting water movement inside the pipes and they convert this movement into readable numbers that show flow rate in gallons per minute (GPM) or liters per second.

Most water flow meters usually connect directly to your pipe system. Some types go inside the pipe and some others attach to the outside without cutting the pipe.

The main job of a water flow meter is to give you accurate flow data because this data helps you to control water usage, detect leaks, and keep your system running smoothly.

For Whom Are Water Flow Meters Important?

If you work with water systems, you already know that precision matters. Measuring water flow is about making sure your work runs smoothly, meets the highest standards, and avoids costly mistakes.

For whom are water flow meters important?

- For Plumbers:

When you’re putting in a water heater or planning out a bathroom, you need to know the flow rate. For example, if you get the pipe size wrong, the shower will turn into a drizzle, but if you get it too big, you will pay more for extra materials.

- For System Designers:

Flow data helps you balance the whole system, spot problems early, and make sure every fixture has enough pressure.

- For Maintenance Teams:

Regularly checking flow rates helps you catch leaks or blockages before they get worse. If the flow suddenly drops, it’s often a sign that something needs fixing.

What Are The Water Flow Meter Types?

Not all water flow meters work the same way. Different situations call for different tools. Here’s a breakdown of the most common water flow meter types you’ll encounter:

Meter Type | How It Works | Best Used For | Accuracy Level |

Mechanical | Physical turbine spins with water flow | Residential systems, basic commercial | Good for most applications |

Ultrasonic | Sound waves measure flow speed | Clean water systems, minimal maintenance | Very high accuracy |

Electromagnetic | Magnetic field detects conductive liquids | Large commercial systems | Excellent for high-volume flows |

Thermal | Heat transfer measures flow rate | Small pipes, precise measurements | High accuracy for low flows |

Positive Displacement | Chambers fill and empty with water | Billing applications, custody transfer | Most accurate for billing |

- Mechanical Water Flow Meters

These are the workhorses of the industry. A small turbine inside the meter spins as water flows past it. The faster the water moves, the faster the turbine spins. Simple and reliable.

| Pros | Cons |

| • Affordable and widely available• Easy to install and maintain• Work well in most water conditions• Long track record of reliability | • Moving parts can wear out over time• Not ideal for very dirty water• May lose accuracy at very low flows |

Best Applications: Residential water services, small commercial buildings, irrigation systems where cost is a concern.

- Ultrasonic Flow Meters

These high-tech meters use sound waves to measure water flow. They send ultrasonic signals through the water and calculate flow based on how those signals travel. No moving parts means less maintenance.

| Pros | Cons |

| • No moving parts to break or wear out• Very accurate across a wide range of flows• Can measure dirty or chemically treated water• Often include advanced diagnostic features | • Higher upfront cost• Require clean pipe surfaces for accurate readings• May need professional calibration |

Best Applications: Municipal water systems, industrial processes, anywhere you need high accuracy with minimal maintenance.

- Electromagnetic Flow Meters

These meters create a magnetic field across the pipe. As water (which conducts electricity) flows through this field, it generates a voltage that’s proportional to the flow rate. It’s like a generator in reverse.

| Pros | Cons |

| • Extremely accurate for large flows• No obstruction to water flow• Work well with dirty or corrosive water• Long service life | • Only work with conductive liquids• Expensive for smaller applications• Require professional installation |

Best Applications: Large municipal systems, industrial processes, wastewater treatment plants.

The Components of Water Flow Measurement Systems

- The Water Flow Sensor

The water flow sensor is the core component of any flow meter. It detects water movement and converts it into a readable signal.

The types include turbine sensors, which spin with the flow; ultrasonic sensors, which use sound waves; magnetic sensors, which detect changes in electrical fields; and thermal sensors, which measure heat transfer.

The right choice depends on the application, required accuracy, and budget.

- Display and Recording Systems

Modern flow meters often have digital screens showing real-time flow rates, total usage, and system health. Many flow meters also connect to computers for automatic logging and remote monitoring.

- Water Flow Control Valve Integration

A flow control valve works with the meter to keep pressure and flow steady. If the meter spots a problem, the valve can adjust automatically—ideal for irrigation, industrial systems, and buildings that need constant water pressure.

Measuring Water Flow Rate and GPM

When you work with a water system, knowing the water flow rate is essential for sizing equipment correctly and diagnosing issues.

Here are the units that water flow is measured:

Unit | Common Use | Conversion |

GPM (Gallons Per Minute) | Residential and small commercial | Standard reference |

GPH (Gallons Per Hour) | Slow flows, leak detection | 1 GPM = 60 GPH |

CFM (Cubic Feet Per Minute) | Large commercial systems | 1 GPM = 0.134 CFM |

LPM (Liters Per Minute) | International applications | 1 GPM = 3.785 LPM |

Installation and Maintenance Best Practices

| Installation Category | Requirements | Key Points |

Pipe Preparation | Straight pipe runs, debris removal | • 10 pipe diameters upstream, 5 downstream• Remove all debris and scale from interior• Verify pipe size matches meter specs |

Orientation | Proper positioning and alignment | • Follow manufacturer specifications exactly• Some meters require horizontal installation• Align flow arrows with water direction• Ensure accessibility for maintenance |

Electrical Connections | Safe, weatherproof installation | • Proper grounding for electronic meters• Moisture protection for all connections• Use appropriate conduit and enclosures• Test all connections before commissioning |

- Maintenance Schedule

For a water flow meter to be accurate and reliable, regular maintenance is very important. Make sure to do monthly checks which should include verifying readings against expected usage, inspecting for leaks or damages and making sure that the display is functioning properly.

Every year, have a professional check your meter to make sure it’s reading correctly, clean the inside parts, replace anything that’s worn out, and update the software if it’s an electronic meter.

How To Choose the Right Water Flow Meter for Your Project

With so many options available, selecting the right water flow meter can feel overwhelming. Here’s a practical approach that simplifies the decision.

- Application Assessment

Start by clearly defining your requirements:

| Assessment Area | Key Questions to Ask |

| Flow Range | What’s the minimum and maximum flow you need to measure? |

| Accuracy Requirements | How precise do the readings need to be? |

| Environmental Conditions | Indoor/outdoor, temperature extremes, chemical exposure? |

| Budget Constraints | What’s the total project budget including installation and maintenance? |

| Integration Needs | Does the meter need to connect to other systems? |

New England Manufacturing, has operated for over 100 years offering water flow equipment that ensures your meter provides reliable and accurate readings.

Check out our water flow equipment here to find the best for you.

The Flow Meter Which Is Best (Depending On The Application)

Application Type | Recommended Meter | Key Benefits |

Residential Service | Mechanical (Turbine) | Cost-effective, proven reliability |

Commercial Buildings | Ultrasonic or Electromagnetic | High accuracy, low maintenance |

Industrial Process | Electromagnetic | Handles difficult conditions |

Irrigation Systems | Mechanical with control valve | Simple operation, flow control |

Temporary Monitoring | Portable ultrasonic | Easy installation, no pipe cutting |

Important Points to Remember

It is very important for you to know flow meters and different types of it, because this will allow you to make informed decisions that benefit your customers and projects.

You need to have the correct flow measurement solution to collect data which will give you the confidence to establish an optimal system.

Keep in mind:

- Match the water flow meter type to your application specifications

- Consider the upfront costs and the long-range maintenance of the water flow meter

- Getting the installation right are crucial for accuracy

- Maintenance will prolong the life of the water flow meters and ensure accuracy

- Professional testing equipment is an assurance of continual reliability

If you’re a water professional looking for accurate flow measurements without worrying about unreliable equipment, New England Manufacturing has been offering high-quality water flow equipment for over 100 years. We are a veteran-owned company and care deeply about helping with your water flow testing equipment and professional calibration needs.To learn more about our products, you can check out our main website by clicking here.